"It is not the critic who counts; not the man who points out how the strong man stumbles, or where the doer of deeds could have done them better. The credit belongs to the man who is actually in the arena, whose face is marred by dust and sweat and blood; who strives valiantly; who errs, who comes short again and again, because there is no effort without error and shortcoming; but who does actually strive to do the deeds; who knows great enthusiasms, the great devotions; who spends himself in a worthy cause; who at the best knows in the end the triumph of high achievement, and who at the worst, if he fails, at least fails while daring greatly, so that his place shall never be with those cold and timid souls who neither know Victory nor Defeat."

-Theodore Roosevelt

"The Man in the Arena," 1910

I’d like to take a moment to talk “Victory nor Defeat.”

A good friend recently asked what I thought about the handful of “sh*tty” (yea, she’s a classy lady) reviews/ratings of Able Ebenezer. The answer is easy: I don’t think about them at all.

Teddy Roosevelt spoke about two kinds of individuals: those who take it upon themselves to step into the arena and be the doers of the world, and those who would rather remain on the sidelines, simply critiquing what is done.

Mike and I wanted to be the former. It’s why we joined the military and trained to become officers and leaders during a time of war. It’s also why we chose to become entrepreneurs; a decision we each made individually many years ago. We knew it would be a great deal of work, and come with a bevy of challenges. This is why we were patient, waiting to fall in love with something to the point where we were willing to bet all we had and all we were on making it a reality (see “Burn the Ships”).

It turned out to be craft beer.

I fell in love with craft beer in the Army. I didn’t have much downtime, but when I did I spent it drinking beers and sharing stories with my battle buddies. Craft beer became my escape; it brought us together, making life a little happier one pint at a time. As a soldier and leader whose full-time job was to train in, and implement, the “art” of combat, I envied and admired the people whose work consisted of manufacturing happiness.

Army buddies Galen, Matty, Jeff and I at the Blues & Brews Festival in Albuquerque, NM. Yes, I know I look like a child.

I finally knew what I wanted to be when I “grew up.”

I had a little more than year left in the military following my deployment to Iraq, and I wanted to focus any scrap of free time on learning how to become a brewer one day. It started with research (books, videos, forums, etc), traveling to breweries, writing to brewers (who usually never wrote back) and beginning to make a mess in my small kitchen.

I looked to see if the GI Bill would cover Brewmasters school (it doesn’t). I emailed my resume to breweries all over the Rocky Mountains stating my willingness to take on any job they may have just to get my foot in the door (they don’t usually reply to those either). I quickly realized I would need more time and experience to make this a reality, but would need to keep working (because brewing costs money).

Military officers are highly sought after in the corporate world, so I leveraged that to secure a job at a biotechnology company in Cambridge. This killed two birds: I was able to move to the “Live Free or Die” state (a dream of mine since college), and the ability to gain experience in a similar industry (beer brewing is the earliest form of biotech).

I bought a small cabin in Auburn, NH that had one key asset I considered to be a must-have: a garage. To date, I have yet to park a vehicle in it. That garage became our brew house; the basement, our fermentation suite.

The original home-brew system. Now on the brewery floor in Merrimack, serving as our pilot system. We use it to design every new beer we develop.

I began taking graduate classes at Tufts in the evenings in bioengineering, which included classes in fermentation science and systems engineering.

I spent thousands on building the original 5-gallon brewing system. That’s stupid, right? I could have just bought a fancy one off the shelf for that kind of money. Quite the contrary, I knew the lessons I would learn designing the system and process, as well as soldering, brazing and welding it all together, would pay dividends in the future. Yes, I built one homebrew system, but I broke down and rebuilt that system several times over before I was happy with the objective results and efficiencies it produced.

I reconnected with Mike, who was out in California finishing up his MBA. It couldn’t have worked out better; while I was in NH spending my free time working on creating the most technically sound beer I could, he was utilizing his to design the best tasting beers he could in his apartment, stove-top.

He had written a business plan as part of his final project, but no one else was willing to step into the arena with him.

I floated the idea of moving in with me and working to make our mutual passion a reality. He made the move immediately following his graduation 4 months later, selling everything that wouldn’t fit into his pickup truck (including his beloved motorcycle) and setting out east. Mike had never been to NH before. Burn the Ships, indeed.

His first day in town we brewed the first batch of “Burn the Ships.” The idea of a smoked IPA was also stupid, but it was one specialty malt I hadn’t used yet, and the intent of that first brew day wasn’t to design a product, it was to familiarize Mike with the system (he’d yet to do an all-grain batch). One step at a time.

That first batch of BtS was undrinkable.

I knew I needed Mike, I just didn’t realize how much. I simply don’t have the patience, discipline and attention to detail to fine tune the complexity of flavors in beer design. Conversely, Mike is the most detailed person I know. While I was waking up at 4am to get ready for my commute to Cambridge, Mike would just be getting to bed, having been up all night researching and tweaking recipes. By the time I got home in the afternoon, he was firing up the system for another batch. At any given time, we had multiple variations of each brand running in our fermenters, trying to pinpoint exactly where we wanted each profile to land; every beer on our board has seen several variations before being given our stamp of approval. Our standard for when a beer is done? We simply love drinking it. Again: happiness, one pint at a time.

You can thank Mike for BtS becoming a reality. Most would’ve given up on the idea. Mike brewed roughly a dozen variations before finalizing its design.

Fermentation of R&D batches in Auburn, NH.

We then began looking for capital to turn the business plan into a reality. We had saved a great deal to get started, but wanted to start at 10-barrel capacity to ensure we wouldn’t need to brew around the clock in order to keep up with demand. After all, a brewery is a still a business, and we knew we would need time each week for sales, distribution, bookkeeping/accounting, bartending, and then some (all the little things that go into a functional and financially-stable brewing operation).

We also didn’t want to take on too much debt; an aspect which has to be delicately balanced, because too much can choke a business’ cash flow to the point of closure. To build a warehouse into 10-barrel brewery the “right way” can be upwards of a million bucks or more...but we believed we could leverage our abilities to do it for less than a 3rd of that (more to follow). We finalized our plan and I began to call every banker whose contact info I could find online.

I'll tell ya, it sucks to be told no; that your plan is too ambitious, doesn’t request enough capital, doesn’t make sense in this saturated market, self-distribution is not manageable at this scale, etc, etc etc. Many banks told us exactly that.

Two institutions believed in us enough to take a chance. I don’t know what it was they saw in us, but they knew we were on to something, and were willing to do whatever it took to make it a reality. We give our thanks to Laurel & Chris at the Regional Economic Development Center, and Peter and John at Enterprise Bank for believing in the idea of Able Ebenezer; you guys will always be family to us.

We found a facility we liked up here on Columbia Circle and were ready to sign the lease, but the government shutdown in the fall of 2013 also shut down the SBA, delaying our financing paperwork from being processed indefinitely. Signing the facility lease required several thousand dollars in a down payment, and there were others were interested in the building as well. To avoid any chance of losing it, Mike and I just went ahead and paid for it ourselves (may have sold some things in the process).

I turned in my resignation letter at work the next day. Another ship burned.

The brewery, before it was a brewery.

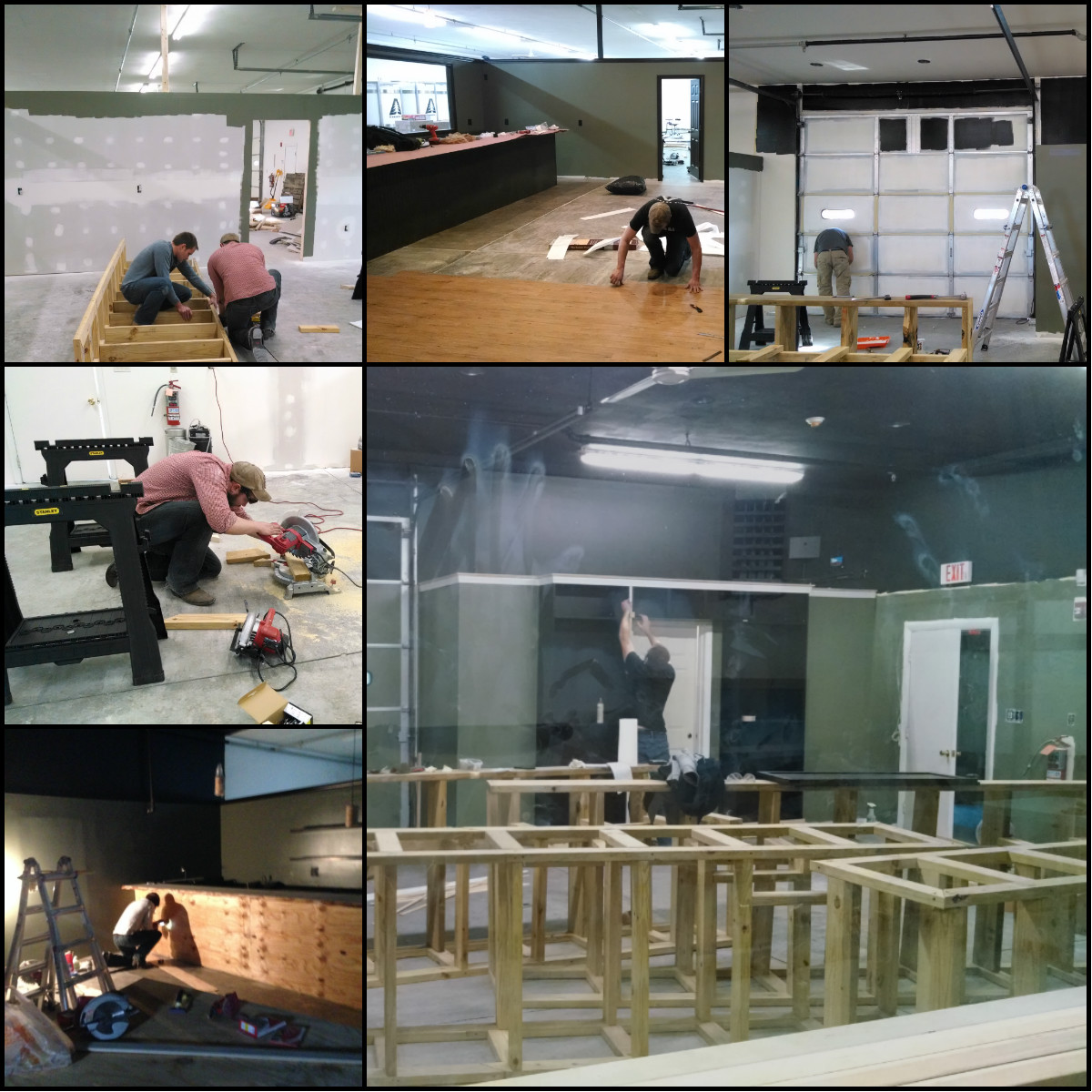

The money came through around New Year’s of 2014, and we went to work turning an empty warehouse into a brewery and bar.

We began by putting down blue painters tape, marking where everything we planned to build would go. We showed the place (and blue tape) to curious bypassers and neighboring businesses; many thought we were crazy.

Getting up the walls of what would become our Ale Room.

We spent a month cleaning the place. We resurfaced the entire ~4000 square feet of concrete floor in the warehouse to give us a fresh, clean layer to seal. We jack-hammered, dug and placed our own 50-foot floor drain. We laid the flooring, painted the walls and built the bar. Mike and I literally did every ounce of construction ourselves aside from the plumbing and electrical (you know, the stuff the law requires only professionals do - for good reason). We made dozens upon dozens of trips to home improvement stores for lumber, paint, nails, screws, tools, etc as we slowly built the place out.

Creating our floor drain. We know way more about concrete floors than we ever wished to.

Each time we completed a project, Mike would joke that if we failed at brewing, we could always start a contracting company. Positive attitude goes a long way.

Building our Ale Room.

The brewing system? I built it myself; the 2nd one I’ve created. A 500-gallon insulated milk tank I found in Wisconsin serves as our mash tun; a food processing tank from Massachusetts as our boil kettle. I welded on the leg extensions and firebox, as well as did all the piping and valve work. A special thank you to Cam at our neighbors - AC Heating & Air Conditioning - for refining my welding technique...and for letting me borrow his welder for a couple months.

Building of our 10-BBL production brewing system.

Thank goodness I “wasted” a couple grand in my garage learning the ins and outs of metal working on a brewing system. Saved us a ton of capital.

We bought the fermenters and process pump used. I had to spent a couple days rebuilding the pump so it would actually work (but saved more capital in the process). I can thank my years working in biotech for knowing how to perform preventative maintenance on sanitary rotary-lobe pumps.

It took us six months to build out 31 Columbia Circle into a functioning brewery. No, we didn't take any pay.

On June 14th, 2014, we opened our doors. You know the rest.

Our Grand Opening.

It's been a hell of a ride thus far, but what has it all for?

Let’s go back to the beginning: happiness, one pint at a time. We’ve successfully created a craft brewery that produces beer we truly love, and share them with the many thousands of you who love them the same.

So, I’m in the arena. I stepped into it willfully, burned every ship I had and worked tirelessly to get here, and now fight daily to remain. I stand here victorious alongside my fellow warriors - Mike, Jake, Heather and Chris - and proudly put my name on everything Able Ebenezer has done and will do.

My battle buddies.

I don’t think about the other people Roosevelt spoke of; the critics of the world. They’ve never mattered to me. They’re simply missing the point of beer existing in the first place: happiness.

There will always be naysayers; you’re not good enough, you’re not ready, you’re not capable. But they are the ones who are afraid; unwilling to take the on the risks and endure the many defeats necessary to taste victory. Roosevelt called them the "cold and timid souls who neither know Victory nor Defeat."

The critics are always loudly inviting people to join them on the sidelines, so I’ll be the one voice welcoming you to join us in the arena: if there’s something in this life that you truly love, don’t let anyone convince you otherwise. I assure you, it’s pretty sweet. Cheers.

-Carl

You can read Mike's original "Victory nor Defeat" story here.